Super F – the magic of silica and other fining agents

Introduction

Silica is one of the most abundant elements in the solar system. Beneath carbon in the Periodic Table, its properties are useful in the construction of stable structures. It has been utilised by Nature in the formation of skeletons for diatomites, oceanic sponges and many micro-organisms. About 95% of the commercial use of silica is in the manufacture of cement for building. It is the most abundant chemical in the Earth’s crust, largely in the form of silicon dioxide, known as quartz; when ground to a fine powder it’s called sand.

When silicon dioxide is heated with sodium oxide, sodium metasilicate is formed. The sodium ions are removed by washing in alkali then the solution acid-washed to form the silica sol. An electro-negative charge is presented on the molecules which have a strong affinity for positively charged species. In solution where opposite charges exist, e.g. beer, floccs are created which precipitate under the influence of gravity.

By reversing this electro-negative charge to electro-positive, the solution will precipitate negatively charged species. This property is utilised by brewers to remove electrically charged species in their beers at certain points in the brewing process. Typically these are proteins & yeasts which would otherwise cause haze and flavour instability in shelf life. Hence silica sols are popular as finings agents in brewing and wine-making to assist in clarification and stabilisation.

For many years, piscine isinglass has been the finings of choice for traditional cask beer brewing. It is collagen with a helical structure and at a pH of 2.5, presenting many positively charged sites to which negatively charged live yeast cells can bind. Isinglass is derived from the swim bladders of certain tropical species of fish, a by-product of the fishing industry. Recently, pressure on these fish stocks, price increases, ready-for-use isinglass short shelf life and the recent consumer trend to more sustainable products have meant a decline in isinglass usage.

Super F in brewery use

Murphy and Son Ltd. have been manufacturers of isinglass for many years and have considerable expertise in clarification technology. Isinglass is the choice finings agent for traditional cask beer at rack but many brewers also clarify beers in tank post-fermentation. Beers that are not destined for cask but for keg, can and bottle require a degree of stabilisation and/or clarification before packaging for longer shelf life. Super F was developed specifically as a tank finings agent for these brewers. It has similar density to beer, finding its way through natural dispersion, quickly attracting live yeast cells creating floccs that rapidly settle out at the bottom. This leaves a brighter beer (but not always brilliant) that is stabilised through yeast removal that can be packaged unfiltered or presented for easier filtration as a bright beer for packaging. Traditional cask beer brewers are also now using Super F as an isinglass replacement to meet the growing demand for vegan-friendly beers from the consumer.

Like many aspects of brewing, many factors determine the efficacy of Super F. In itself, particle size within the Super F has been shown to play a significant role in fining action. We have now harmonised our Super F to two distinct particle sizes which has enable an increased speed of fining and more compact sediment meaning the brewer can clear a beer faster with lower production losses.

Two other major influences in its use are temperature and dose rate. Super F is at its optimal temperature if dosed when the beer is around 6°C. It will still work out with this but will be slower. Dose rate is subject to various factors like beer strength, yeast count, recipe and length of time beer is to be held in tank before use. It is usually determined by benchtop trials then trials in production. Most brewers find a dose rate between 70 – 200ml/hl works well.

To get optimal use throughout the brewing process, Super F must be considered in conjunction with other finings agents and to a lesser degree the recipe of the beer which includes the ionic profile of the brewing liquor. Murphy and Son are experts in liquor treatment and should be consulted separately about this. Suffice to say here that calcium ions (Ca2+) play a big role in the ability of beer to respond to finings agents so attention should be given to this.

Other fining agents

The very nature of brewing from natural materials using live yeast for fermentation results in products that can cause instability in the final beer. Protein is one of these products. It comes from the raw materials used in the brewhouse. Some is required for flavour, colour, yeast growth, mouthfeel and beer foam but there is usually an excess that if not removed, or at least reduced, will cause quality failures in trade through the creation of haze (if the beer is designed to be bright) or off-flavour. Therefore, protein management is a significant aspect of brewing.

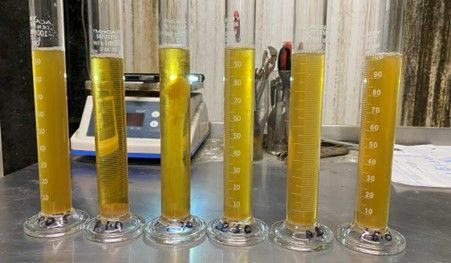

Above: benchtop trial of Super F to determine correct dose rate. The sample on the extreme left is a control (hazy, tiny sediment). The second sample from left is 0.5ml/l followed by 1.0ml/l, very bright with compact sediment. Samples further right over-fined.

Carrageenan

The first point at which this can be managed is in the use of kettle or copper finings. Using the electrostatic principles described above, protein can be removed in the wort before fermentation begins. Copper fining agents are carrageenan, a long chain polysaccharide structure extracted from certain species of seaweed. It is added to hot wort near the end of boiling in low dose rates, typically 1.0 – 4.0g/hl and allowed to dissolve. The lower temperature of cold wort causes the proteins to contort around the long chain polysaccharide through electrical attraction and precipitate out as trub.

Murphy and Son have two grades of this finings: Protafloc and Koppakleer. Protafloc is a semi-refined carrageenan that requires addition to the kettle 10-15 minutes from the end of boiling to dissolve. Koppakleer is a fully refined grade that can be added at the end of boil or to a whirlpool as it will dissolve instantly upon contact with hot wort. Both have the same function. They are available as granules or as tablets for ease of use.

Above: benchtop trial of Protafloc kettle finings determine correct dose rate in wort. The sample on the extreme left is a control (hazy, tiny sediment). The second sample from left is 1.0ml/l, very bright with compact sediment, ideal. Remaining samples to the right, over-fined.

Auxiliary Finings

The second point of protein management can be achieved at end of fermentation. The rough beer at this stage is at a lower pH to wort, typically 3.9 – 4.3 and the cooling down enables more protein to change its morphometry presenting numerous, predominantly positive electrical sites to which an appropriately charged agent can bind. These are the acidified silica sols mentioned in the introduction. Murphy and Son have several formulations all designed to precipitate protein in the manner described. Finings Adjunct is a ready for use, highly popular agent that can be added from end of fermentation onwards, often in multiple steps to break a protein out of solution prior to a yeast fining agent like Super F or to break a particularly troublesome returning haze difficult to fine first time. Another agent is Alginex, an acidified polysaccharide extracted from acacia gum that does exactly the same job. This is a highly concentrated and stable solution that requires dilution prior to use. It’s designed for our export customers due to its long shelf life & stability. Dose rates for both these auxiliary finings is in the range of 50 – 300ml/hl, determined like Super F through bench top trials followed by production trials. They are also influenced by upstream factors like liquor treatment, use of kettle finings recipe type, beer strength, etc.

To wrap it up

It can be seen that the role of silica, presented as a sol as a finings agent, plays a most useful role in the clarification and stabilisation of beer in process at the brewery. The use of finings in brewing cannot be underestimated as beneficial process aids. They not only enhance beer quality but they can improve efficiency and reduce cost once optimised correctly.

Murphy and Son Ltd. have the complete range to offer all aspects of brewing whether it be lager, ale or stout. These products are supported by a wealth of experienced Master Brewers and a laboratory that can assist in identifying issues and recommending solutions to help manage the process for the best possible outcomes.

References: